Description

Fully Automatic Potato Chips & French Fries Production Line

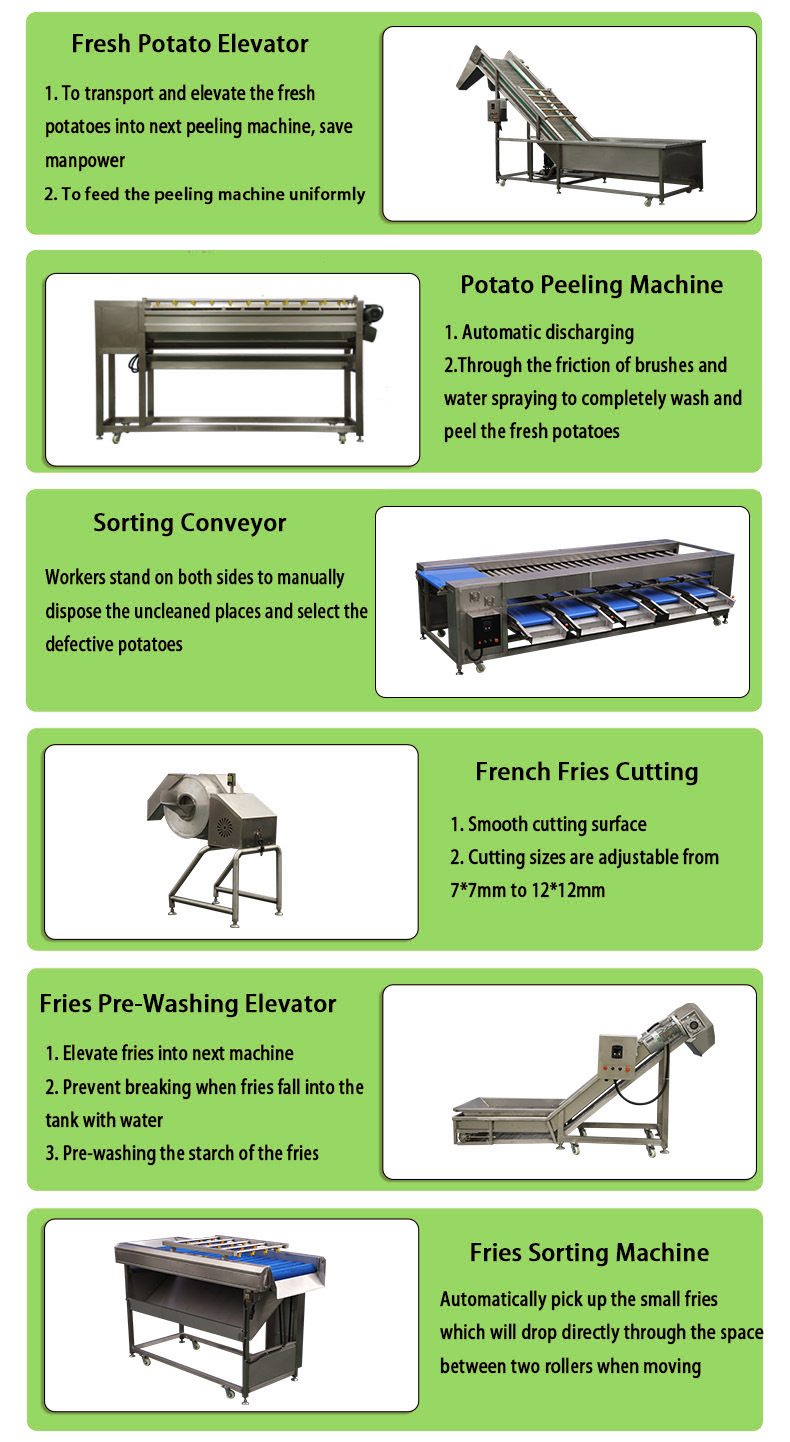

1: Different machines for making potato chips or french fries

2: Small, medium and large capacity from 30kg/h, 50kg/h, to 100kg/h, 300kg/h, to 1000kg/h, 2000kg/h output and workflow can be customized

3: Semi automatic or fully automatic processing machines

4: Electricity or gas, diesel heating source for blanching and frying machine.

5: The size of french fries and the thickness of potato chips are adjustable.

6: For french fries line, we have special equipment to remove the unqualified fries.

7: All machines are made of SUS304, Schneider electrical components and Siemens brand motor.

8: With special designed fryer, quick heating and energy saving, enabled good performance

Product Details

Machine Specification

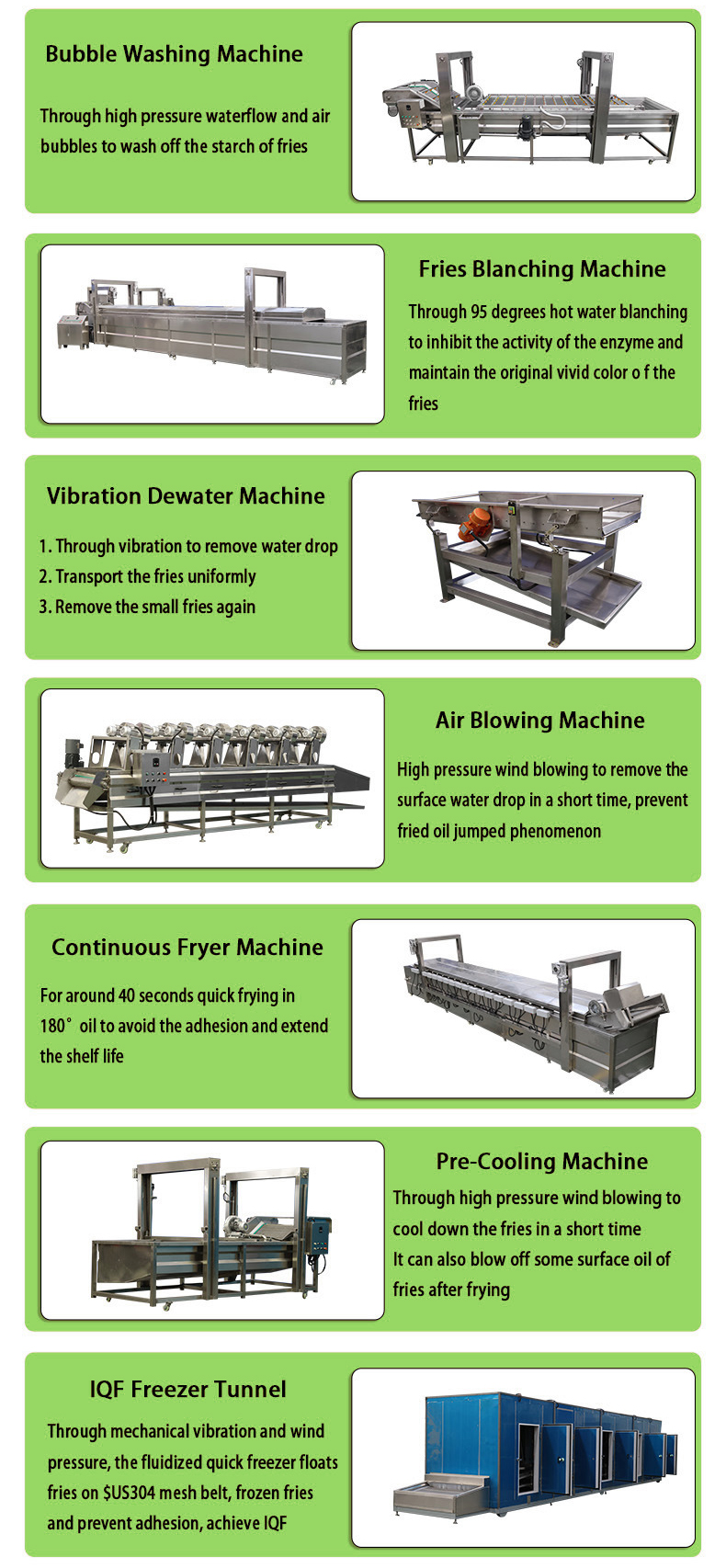

| No. | Machine Name | Function |

| 1 | PVC Elevator | For elevating and conveying fresh potatoes into the next washing peeling machine |

| 2 | Potato Washing and Peeling Machine | Thoroughly washing and peeling the potatoes |

| 3 | Sorting Conveyor | For manually disposing the uncleaned places and selecting the defective potatoes |

| 4 | Fries Cutting Machine | Cutting the potatoes into fries, sizes adjustable from 7*7 to 12*12mm |

| 5 | Water Tank Elevator | water as buffer to prevent fries breakage, and simply removing starch, meanwhile elevating fries into next step |

| 6 | Fries Sorting Machine | Automatically picking up the small pieces fries |

| 7 | Bubble Washing Machine | Through high pressure waterflow and water bubbles to impact and scrub the fries to wash off the starch |

| 8 | Blanching Machine | Through 60-95 degree hot water blanching to inhibit the activity of the enzyme and maintains the original vivid color of the fries |

| 9 | Vibration Dewatering Machine | Through vibration to remove the surface water and also to transport the fries uniformly to the next machine |

| 10 | Air Drying Machine | Through high pressure wind blowing for pre-cooling and removing the excess water in short time, effectively prevent the fried oil jumped phenomenon |

| 11 | Elevating Conveyor | For elevating and conveying the fries into next fryer machine |

| 12 | Continuous Frying Machine | For quick frying the fries around 40 seconds in 180°oil to avoid the adhesion and extend the shelf life |

| 13 | Vibration Deoiling Machine | Through vibration to achieve deoiling purpose, and also to convey the fries uniformly to next machine |

| 14 | Pre-cooling Machine | Through high pressure wind blowing for pre-cooling and deoiling the fries |

| 15 | Freezing Machine | Through mechanical vibration and wind pressure, the fluidized quick freezer floats products on stainless steel mesh belt, frozen products and prevent adhesion, achieve IQF |

| 16 | Automatic Packing Machine | For packing the finished frozen french fries |

Packing & Delivery

ABOUT US

* 15 years factory production experience

* 3 years machine warranty

* 156 exported country experience

* 38000 square meters food processing machine factory

* About Shandong Hoace Intelligent Equipment Co.,Ltd.is established in January 2003, owns more than 2000 square meters of researching and office space, more than 12000 square meters factory.All machines , passed the European Union CE authentication, American certificate and are certified to ISO 9001. Products are sold to USA,Canada, Australia, Europe, South east Asia,Africa etc,more than 160 countries and areas,and supply OEM service for more than 30 manufactures.

Welcome to Visit Our Factory

If you have plan to visit our factory, just contact us is ok, we will arrange everything well according to your schedule. no matter what trantport way that you want to choose, We will have pick you up, if you need us to arrange your hotel, please contact us, 24×7, we always here!

Customer Show

Our Certificate

FAQ

1. Can I buy just one machine? I don’t run a factory.

A: Yes, you can! Many of our machines are plug-and-play, perfect for small businesses or home use. Just let us know your budget and usage, and we’ll recommend a suitable model.

2. Do you ship to my country? How much is the shipping fee?

A:Yes, we ship worldwide. Tell us your city and country, and we’ll provide the best shipping method (by sea, air, or door-to-door) and quote you the exact shipping cost.

3. Will I have to pay taxes? What about customs clearance?

A: Import taxes depend on your country. Normally, you pay local duties, but we’ll prepare all the necessary documents and support you if you need help with clearance.

4. Can I use one machine for multiple types of food?

A: Some machines are multi-functional. For example, our vegetable cutters, fryers, and mixers can handle different items. Tell us what you plan to process and we’ll help you choose.

5. Can I see real videos before I buy?

A: Yes! We have demo videos, real customer feedback, and we can also offer live demo calls to show the machine in action.

6. How do I choose the right food processing machine for my business?

A: Just tell us what product you want to make, your production capacity, and your budget — our sales engineers will suggest the most suitable solution for you.

7. What’s your lead time for production and shipping?

A: Usually 5–15 working days for standard models. Customized equipment may take longer. We’ll confirm the exact timeline when you place an order.

8. Do you offer after-sales service and technical support?

A: Yes. We provide video support, user manuals, operation guides, and online 1-on-1 training. For some countries, we also have local agents or partners.

9. Can I request customized equipment?

A: Absolutely. We support OEM and ODM. You can customize machine size, material, voltage, color, logo, and even full production line layout.

10. What if the machine breaks down? Do you offer spare parts?

A: We provide a full set of spare parts, remote troubleshooting, and video guidance. For simple issues, we’ll teach your team how to repair it. You can always contact us anytime.

khan –

We’ve been running the 300kg/h line for 6 months now. The build quality is solid, and the fries come out golden and crispy every time. Their tech team helped us set it up remotely. Great support!

Carlos Herrera –

I’ve worked with food machinery from China before, but this is the first time I was truly impressed. We ordered the 1000kg/h potato chips & fries line for our factory in Guadalajara. From washing and peeling to frying and packing, the entire process is automated and surprisingly smooth. The fries are consistent in size and color, and our output has doubled without increasing labor costs. What I appreciated most was their willingness to customize some parts of the line based on our local needs. Shipping was on time, and installation instructions were clear. Highly recommended for anyone looking to upgrade or expand their potato processing line.