Description

Commercial Automatic Double-Head Dual-Frequency Vegetable Cutting

The Machine is designed for versatility and efficiency. It features dual-frequency modulation, with one end specialized for leafy vegetables—such as green onions, garlic sprouts, leeks, celery, cabbage, and other greens—and the other end for root and bulb vegetables, including radishes, potatoes, sweet potatoes, taro, bamboo shoots, onions, eggplants, apples, ginger, and more.

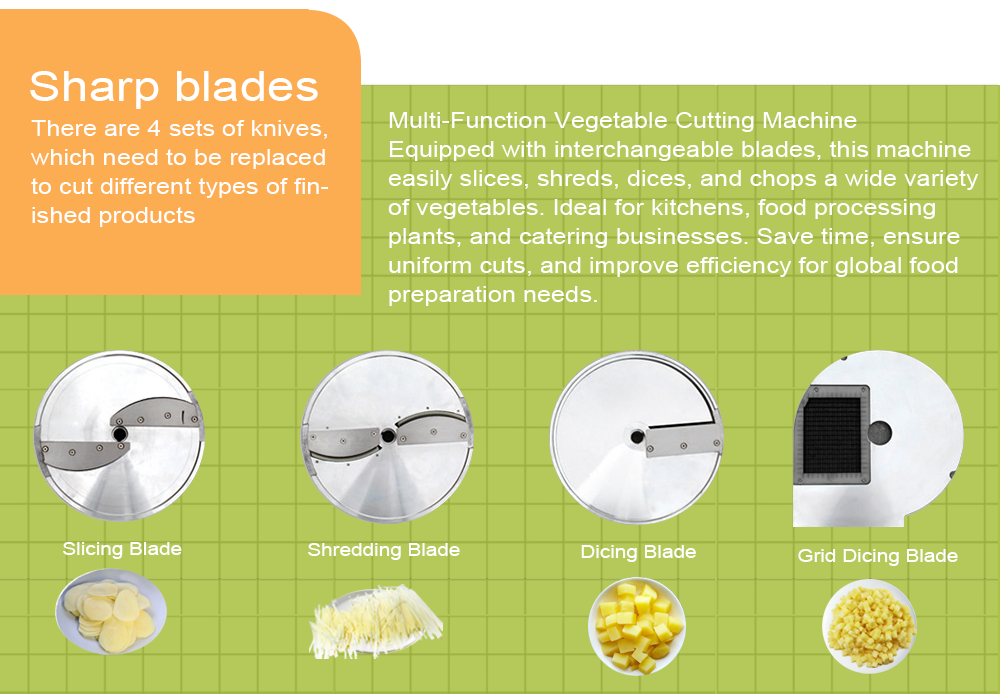

1.Multi-Functional Cutting:Capable of slicing, dicing, shredding, and cutting into sticks or sections. Suitable for both leafy greens and root vegetables.

2.Dual Working Heads:Two independent inlets allow simultaneous processing of different vegetable types, improving productivity.

3.Customizable Output:Thickness and length of cuts can be precisely adjusted to suit various applications and recipes.

4.High Efficiency:One machine delivers the output of multiple workers, significantly reducing labor costs and increasing throughput.

5.User-Friendly Operation:One-button start for quick and easy use; suitable even for untrained operators.

6.Durable & Hygienic Design:Made from corrosion-resistant stainless steel, with easy-to-clean surfaces for food safety and long-term durability.

7.Safety First:Equipped with reliable safety protection devices to prevent accidents during operation.

8.Adjustable Conveyor System:Features a high-quality PE conveyor belt with adjustable speed to handle different cutting requirements.

9.Superior Cutting Quality:Simulates traditional hand-cut techniques for better texture and taste retention.

This vegetable cutting machine for commercial use supports slicing, shredding, dicing, and sectioning, all with customizable sizes to meet various processing needs. Both the conveyor belt and rotary blade speeds are independently adjustable through frequency converters, ensuring optimal cutting performance for different materials.

Product Details

Machine Specification

| Item | Specification |

|---|---|

| Product Name | Commercial Automatic Double-Head Dual-Frequency Vegetable Cutting Machine |

| Motor Power | 1500W + 120W + 120W |

| Applicable Materials | Root and Leafy Vegetables |

| Production Capacity | 500–800 kg/h |

| Cutting Length | 2–30 mm |

| Dicing Size | 8 / 10 / 12 / 15 / 20 mm |

| Rated Voltage | 220V / 380V |

| Rated Frequency | 50Hz |

| Machine Weight | 95 kg |

| Machine Dimensions | 91 × 61 × 98 cm |

| Shredding Thickness | 2–6 mm |

| Slicing Thickness | 2–6 mm |

Packing & Delivery

ABOUT US

* 15 years factory production experience

* 3 years machine warranty

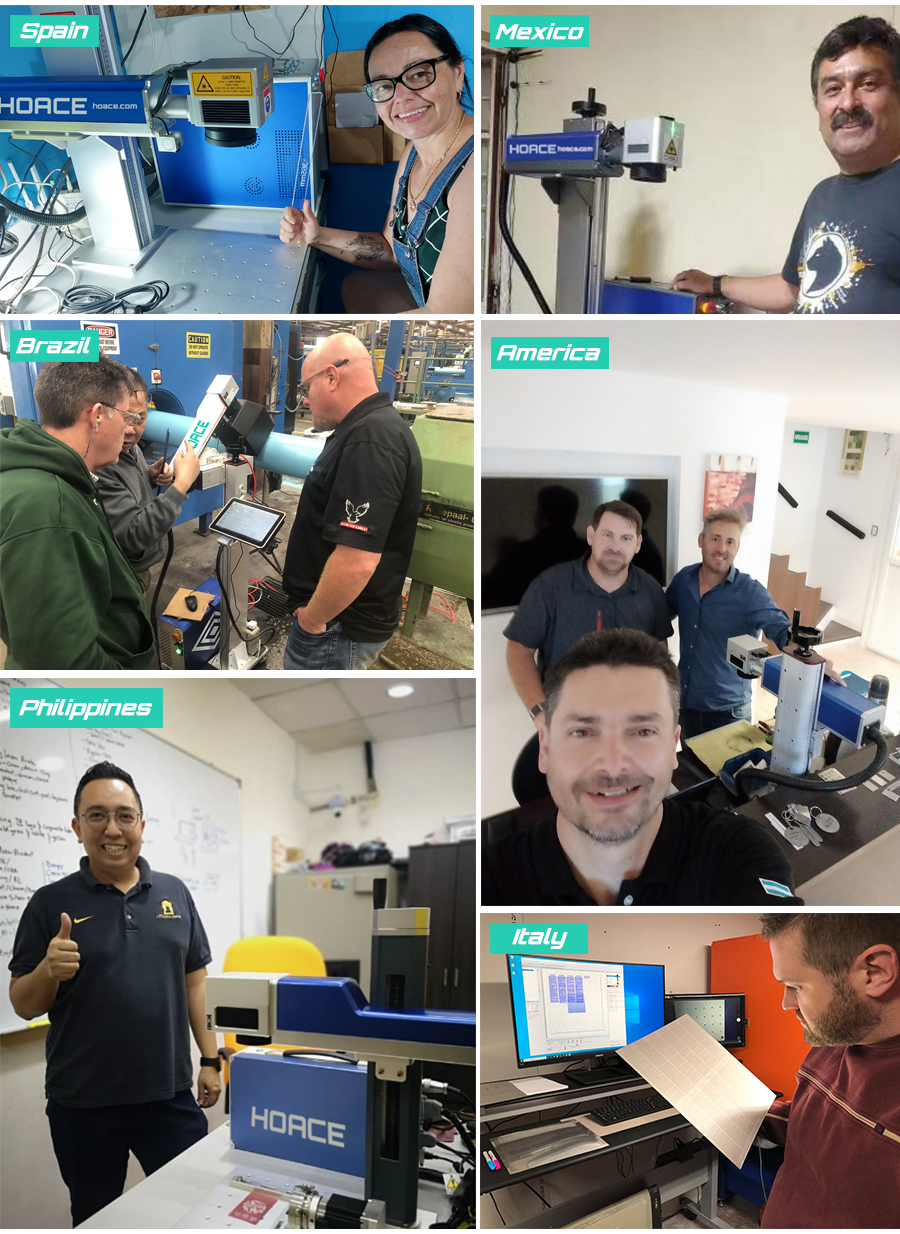

* 156 exported country experience

* 38000 square meters food processing machine factory

* About Shandong Hoace Intelligent Equipment Co.,Ltd.is established in January 2003, owns more than 2000 square meters of researching and office space, more than 12000 square meters factory.All machines , passed the European Union CE authentication, American certificate and are certified to ISO 9001. Products are sold to USA,Canada, Australia, Europe, South east Asia,Africa etc,more than 160 countries and areas,and supply OEM service for more than 30 manufactures.

Welcome to Visit Our Factory

If you have plan to visit our factory, just contact us is ok, we will arrange everything well according to your schedule. no matter what trantport way that you want to choose, We will have pick you up, if you need us to arrange your hotel, please contact us, 24×7, we always here!

Customer Show

Our Certificate

FAQ

1. Can I buy just one machine? I don’t run a factory.

A: Yes, you can! Many of our machines are plug-and-play, perfect for small businesses or home use. Just let us know your budget and usage, and we’ll recommend a suitable model.

2. Do you ship to my country? How much is the shipping fee?

A:Yes, we ship worldwide. Tell us your city and country, and we’ll provide the best shipping method (by sea, air, or door-to-door) and quote you the exact shipping cost.

3. Will I have to pay taxes? What about customs clearance?

A: Import taxes depend on your country. Normally, you pay local duties, but we’ll prepare all the necessary documents and support you if you need help with clearance.

4. Can I use one machine for multiple types of food?

A: Some machines are multi-functional. For example, our vegetable cutters, fryers, and mixers can handle different items. Tell us what you plan to process and we’ll help you choose.

5. Can I see real videos before I buy?

A: Yes! We have demo videos, real customer feedback, and we can also offer live demo calls to show the machine in action.

6. How do I choose the right food processing machine for my business?

A: Just tell us what product you want to make, your production capacity, and your budget — our sales engineers will suggest the most suitable solution for you.

7. What’s your lead time for production and shipping?

A: Usually 5–15 working days for standard models. Customized equipment may take longer. We’ll confirm the exact timeline when you place an order.

8. Do you offer after-sales service and technical support?

A: Yes. We provide video support, user manuals, operation guides, and online 1-on-1 training. For some countries, we also have local agents or partners.

9. Can I request customized equipment?

A: Absolutely. We support OEM and ODM. You can customize machine size, material, voltage, color, logo, and even full production line layout.

10. What if the machine breaks down? Do you offer spare parts?

A: We provide a full set of spare parts, remote troubleshooting, and video guidance. For simple issues, we’ll teach your team how to repair it. You can always contact us anytime.

Matthew –

After receiving the machine, I used it immediately. The results were excellent. The cuts were very even. It saved me a lot of manual labor.